|

I had no idea what IDEO was before I randomly received an email telling me I had been recommended for a position. Turns out they are probably the most renowned product design firm in the world. For over thirty years IDEO and its studios have been turning out ground breaking products as well as popularizing and productizing "design thinking" - approaching challenges by generating creative solutions rather than focusing purely on the perceived problem.

I was working at Meka at the time, but things were looking pretty slow right then. So I figured, if I'm ever going to learn product design, it may as well be from the best.

I learned an insane amount about not only the IDEO process, but the act of bringing a large volume product to market. I had the opportunity to work side-by-side with some of the masters: Jim Yurchenco - manufacturing guru, Matt Adams - Solidworks wizard, and Peter Bronk - master model maker, Andy Switky - program manager and social magician, and numerous other product design masters. I learned the foundations of good Solidworks hygeine, Master Sketch modeling and surface modeling - which I have since adapted to rapid robotics development. I also learned how to expand my experience operating injection molding machines at PTG to the intricacies of injection molded part design with jogged parting lines, pass-cores, lifters and much more. As Matt Adams once said, I was put through "an intensive graduate curriculum in product design."

I left IDEO after we released parts to tooling and I accepted an offer to return to Meka to help lead the new Redwood Robotics project. IDEO was an amazing work environment and I still hope to collaborate with them in the future.

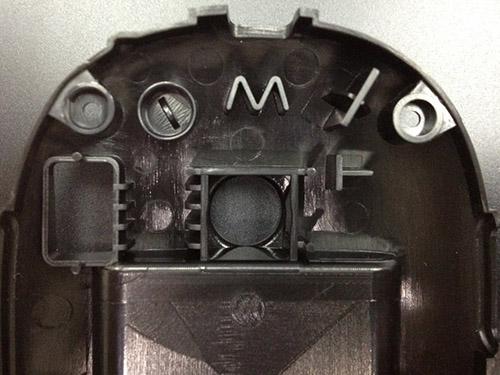

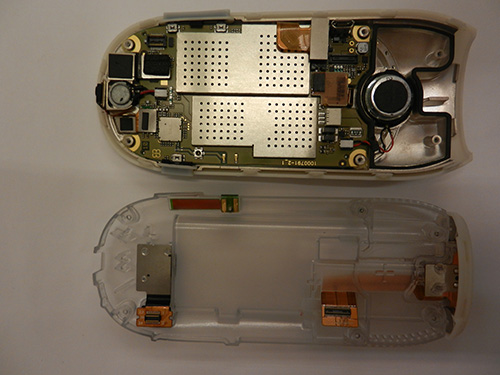

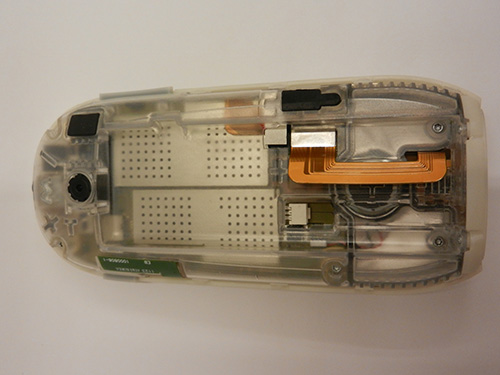

- Primary design engineer for a high volume consumer electronic product utilizing all the tricks and trades of a modern technology.

- Designed for manufacture nearly all internal components of this device, heavy in surface modeling and tolerance analysis. Manufacture methods include: injection mold, die cut, overmold, thixomold, etc..

- Part of team specifing major components such as acoustics, imaging systems, displays, touch panels, etc.

- Interfaced directly with international hardware partners, vendors, manufacturers.

- Interacted and balanced engineering needs with industrial design requirements.

- Traveled overseas to solve complex problems with hardware partners.