|

Makani Power is developing tethered, airborne wind turbines for utility scale, off-shore energy capture.

My involvement began as a summer intern immediately after graduating from UCB with an MSME in the spring of 2008. I took a risk and bailed on a "better" job offer because I wanted to try to help save the f'n planet alongside a team of amazingly creative scientists and engineers. As it turned out, at the end of the summer, Makani hired me as a fulltime engineer. I was in the energy systems group which was responsible for energy conversion from the turbine blade, through the power electronics and the strucutral attachment to the main structure.

Unfortunately, due to the economic crisis of 2008/2009 there were two rounds of layoffs. I was cut in the second round along with most of the remaining mechanical engineers. Makani was also a badass place to work and as a testament to the culture, I am still good friends with the majority of the team and still manage to catch most of the social events they hold over at the tower.

Amongst the many smaller projects that were fulfilled during my employment my primary contributions included:

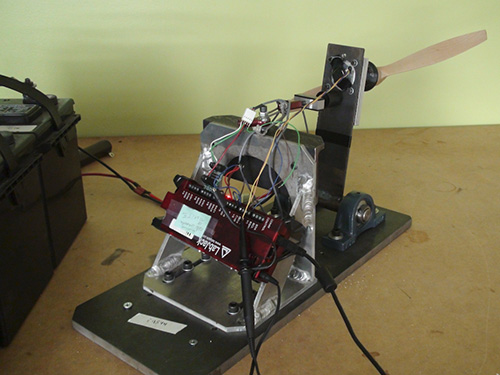

- Designed and machined all mechanical components and experiments for Energy Systems Group.

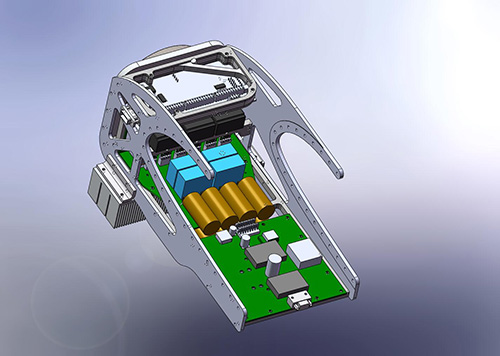

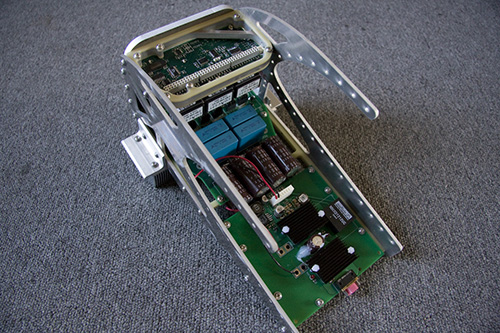

- Designed, analyzed, optimized, and fabricated high-voltage power electronics packaging: PCB layout and load bearing support structures integrated with designs from other engineering groups for use in high-performance aerodynamic maneuvers and power generation.

- Developed, calculated and optimized thermal analysis and machined the corresponding heatsink for power electronics power switching modules (still flying on Wing 7).

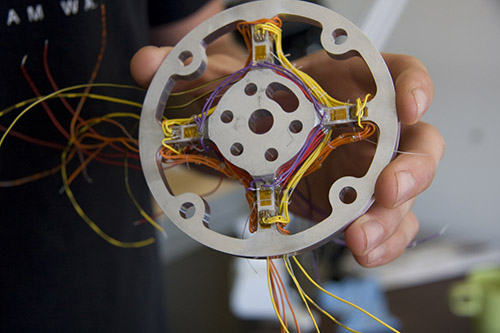

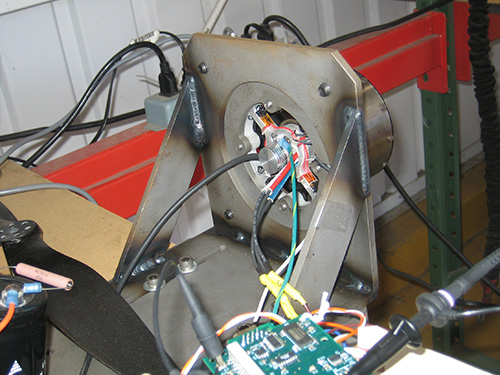

- Designed and fabricated a six-axis load cell (multi-component balance) for in-flight force measurements using strain gauges. Also designed/fabricated a torque transducer for a DC motor dynamometer.

- Designed and fabricated a six-axis load cell (multi-component balance) for in-flight force measurements using strain gauges. Also designed/fabricated a torque transducer for a DC motor dynamometer.

- Performed numerous technical motor experiments and analyzed results including rewiring a 12 pole motor.