|

The Polymer Technology Group was acquired by DSM in 2008.

PTG was primarily a medical polymer research and development company. Their focus was segmented polycarbonate and silicone polyurethanes for chronically implanted medical devices. Most anything that is implanted in a human is made of or coated with with their materials. Biospan and Carbosil are their bread and butter materials. Small startups would want to use these impressive materials but often had no facilities or processing expertise and so they would contract with our Medical Device Manufacturing Group to develop products and take them through clinical trials.

I worked primarily in the Medical Device Manufacturing Group at PTG. However, I begain as an intern (in high school) when there were only twelve employees (I left for grad school with 100 employees) which meant I would wander through the building helping various scientists and engineers. I ended up operating nearly every process in the facility including performing polymer synthesis from scratch (read: mixing chemicals and precipitating out polymers), dipping and web coating medical devices in cleanrooms, compression molding, injection molding, extruduing tubing, cleaning barrels, etc.

As a fulltime engineer I focused on working with clients to develop manufacturing processes for their implantable medical devices. I also took products through ISO9001:2000 qualification procedures for various stages of clinical trials. Many hours were spent in ISO 7 clean rooms working with and programming semi-automated dipping and cnc adhesive dispensers. I spent nearly a year bringing up an Arburg 55ton injection molding machine and developing operating parameters for our custom polymers.

- Lead engineer for two implantable medical device projects following ISO 9001:2000 methods.

- Trained technicians on manufacturing processes.

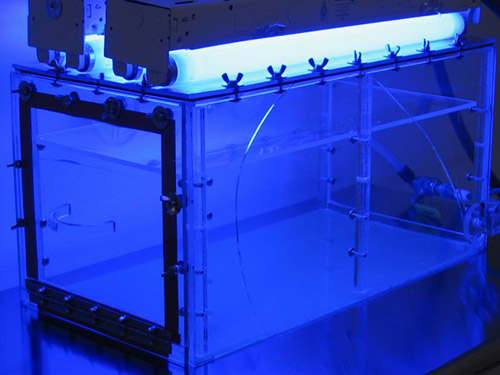

- Procured, installed, operated and qualified 55-ton injection molding machine, auxiliary equipment and ISO Class 7 Cleanroom.

- Designed and fabricated fixture equipment for manufacture of implantable medical devices.

- Developed experiments for manufacturing processes and analysis of material properties.

- Developed testing devices and procedures for membrane desalination technology.